Polar Performance Materials Expands Laboratory Capabilities

In the world of advanced materials, where even microscopic variations can impact million-dollar processes, quality and consistency isn’t just important, they’re often mission-critical.

Today, Polar Performance Materials announced a significant expansion of its laboratory capabilities, reinforcing our commitment to consistently and efficiently deliver consistently high-quality analytical data with both accuracy and precision.

This is a key enabler for Production and R&D teams to optimize formulations and processes, ensuring products meet customer specifications in semiconductor, aerospace, medical, sapphire, and other advanced markets.

Strategic Investment in Customer Success

Our expanded lab strengthens our ability to deliver on current requirements and partner with customers as they advance the next generation of technologies. As industries push the boundaries of what’s possible with ultra-high purity alumina, the demand for faster innovation, application-specific data, and uncompromising quality has never been higher.

Polar Performance Materials expanded its lab capabilities, reinforcing its customer commitment to ensure consistent, accurate and reliable, high-quality Alumina supply.

“Our customers face constant pressure to innovate and rely on us to deliver alumina with consistency and reliability,” says Sean McDonough, VP of Quality. “With our expanded lab and advanced analytics, we can detect even the smallest variations before they become problems. That means customers can trust us to protect the quality of our products.”

The expanded laboratory serves three critical functions:

Accelerated Innovation: Enhanced capabilities enable faster fundamental research into alumina performance characteristics and rapid response to specific customer requests, reducing development cycles from months to weeks.

Application-Specific Data: Advanced analytical instruments provide customers with precise, relevant data for their unique applications, supporting better decision-making and process optimization.

Enhanced Quality Assurance: Expanded testing capabilities ensure consistent delivery of ultra-high purity products that meet the exacting standards of advanced manufacturing processes.

State-of-the-Art Analytical Capabilities

The laboratory expansion introduces advanced instrumentation that significantly enhances our analytical precision and throughput:

Elemental Analysis Excellence. Our Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) system provides critical precision in elemental composition analysis. By exciting atoms in high-temperature argon plasma and measuring characteristic light emissions, we can quantify trace elements with exceptional accuracy—critical for applications where even parts-per-million variations matter.

Surface Characterization Advancement. The new Brunauer-Emmett-Teller (BET) Surface Area Analyzer enables precise measurement of specific surface areas using nitrogen adsorption. Combined with our existing BET unit, we have dramatically improved our capacity to support customer development programs.

Particle Analysis Precision. Our Particle Size Analyzer (PSA) employs laser diffraction technology to determine size distributions with remarkable accuracy. Understanding particle characteristics is essential for optimizing processes from ceramic sintering to sapphire growth applications.

High-Throughput Sample Preparation. The UltraWAVE 3 (UW3) microwave-assisted digestion system represents a quantum leap in sample preparation efficiency. Utilizing Single Reaction Chamber technology, it can simultaneously digest more sample types under uniform high-temperature and high-pressure conditions, accelerating our response time to customer requests.

Comprehensive Material Characterization. Additional capabilities include pycnometry for true density measurements, flowmeter analysis for bulk density and flow characteristics, and moisture analysis for precise water content determination; providing a complete picture of material properties.

Operational Excellence Through Systematic Approach

Beyond advanced equipment, our laboratory operates on principles of precision and reliability:

Skilled Personnel: Our experienced laboratory chemists bring deep expertise in advanced materials characterization, ensuring accuracy and reliability in every analysis.

SOP-Driven Processes: All testing follows rigorous Standard Operating Procedures with integrated Statistical Quality Control, ensuring process consistency and compliance with customer specifications.

Data Integrity: A centralized data management system provides transparent, accessible results with robust sample traceability from receipt to reporting.

Contamination Prevention: An independent sample preparation room eliminates contamination risks, supporting the integrity of analytical results critical for ultra-high purity applications.

Calibration Excellence: All instruments undergo routine calibration with thorough documentation, maintaining measurement accuracy and traceability.

Investment in Human Capital

Alongside equipment investment, we’re expanding our team’s R&D expertise. Advanced materials characterization requires not just sophisticated instruments, but the knowledge to interpret results and translate them into actionable insights for customer applications.

“Technology is only as good as the people who operate it,” notes Chloe Hsu, Principal Scientist. “We’re investing in both cutting-edge equipment and expertise to unlock its full potential for our customers.”

Reinforcing Partnership Through Capability

This laboratory expansion represents another key step in Polar Performance Materials’ evolution from supplier to strategic innovation partner. In markets where material performance directly impacts product reliability and manufacturing yield, having a partner who can provide rapid, consistently precise, and analytical support becomes a competitive advantage.

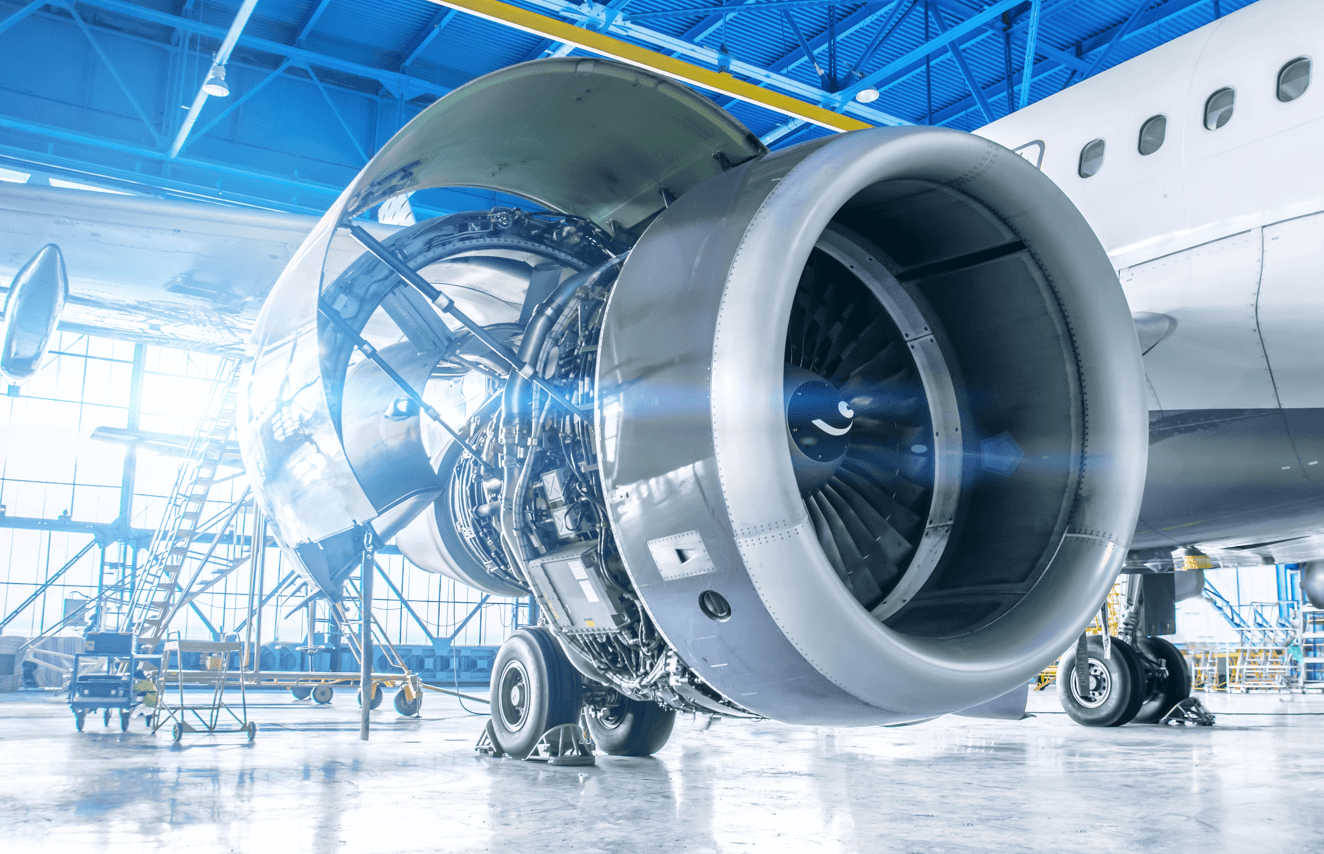

For semiconductor manufacturers optimizing wafer production, aerospace companies developing next-generation components, or medical device producers ensuring biocompatibility, these enhanced capabilities translate into faster development cycles, better process control, and ultimately, superior end products.

Looking Forward

As advanced industries continue pushing performance boundaries, the role of analytical precision becomes increasingly critical. Polar Performance Materials’ expanded laboratory capabilities position us to support not just today’s applications, but tomorrow’s breakthrough innovations.

Whether it’s developing new alumina formulations for emerging semiconductor processes, characterizing materials for space-grade applications, or providing the analytical foundation for next-generation medical devices, our enhanced capabilities ensure we’re ready to support our customers’ most ambitious projects.

The investment in laboratory capabilities reflects our broader commitment: being the partner that advanced industries turn to when precision, accuracy, consistency, and reliability matter most. In a world where material performance can make the difference between success and failure, we’re ensuring our customers have every analytical advantage.

For more information about Polar Performance Materials’ laboratory capabilities or to discuss your specific analytical needs, contact [email protected] or click here:Contact Polar | Trusted High-Purity Alumina Supplier