Ceramics have long been valued for their durability; however, in aerospace engineering, only the most advanced materials are considered suitable. Technical ceramics—particularly those made with high-purity alumina (≥99.99%)—offer exceptional hardness, thermal resistance, and chemical stability. These properties make them indispensable for components like temperature sensors, turbine blades, and electrical insulators operating in extreme environments where failure is not an option.

What Sets Technical Ceramics Apart? Purity.

Unlike traditional ceramics, technical ceramics are engineered from ultra-pure materials to enhance performance. High-purity alumina stands out due to its extreme durability under mechanical, thermal, and chemical stress. This high-purity material maintains integrity where others degrade, enabling long-term reliability in high-stress aerospace environments.

How Polar’s High Purity Alumina Powers Technical Ceramics

Polar’s high-purity alumina, produced with advanced refining beyond the Bayer process, forms the foundation for technical ceramic blends. Whether it’s alumina-zirconia or alumino-silicate, the performance depends on a core of ultra-pure Al2O3. This material can only be ground with diamond tooling due to its hardness and is shaped through precision manufacturing methods like isostatic pressing and injection molding.

Strength that Survives the Sky

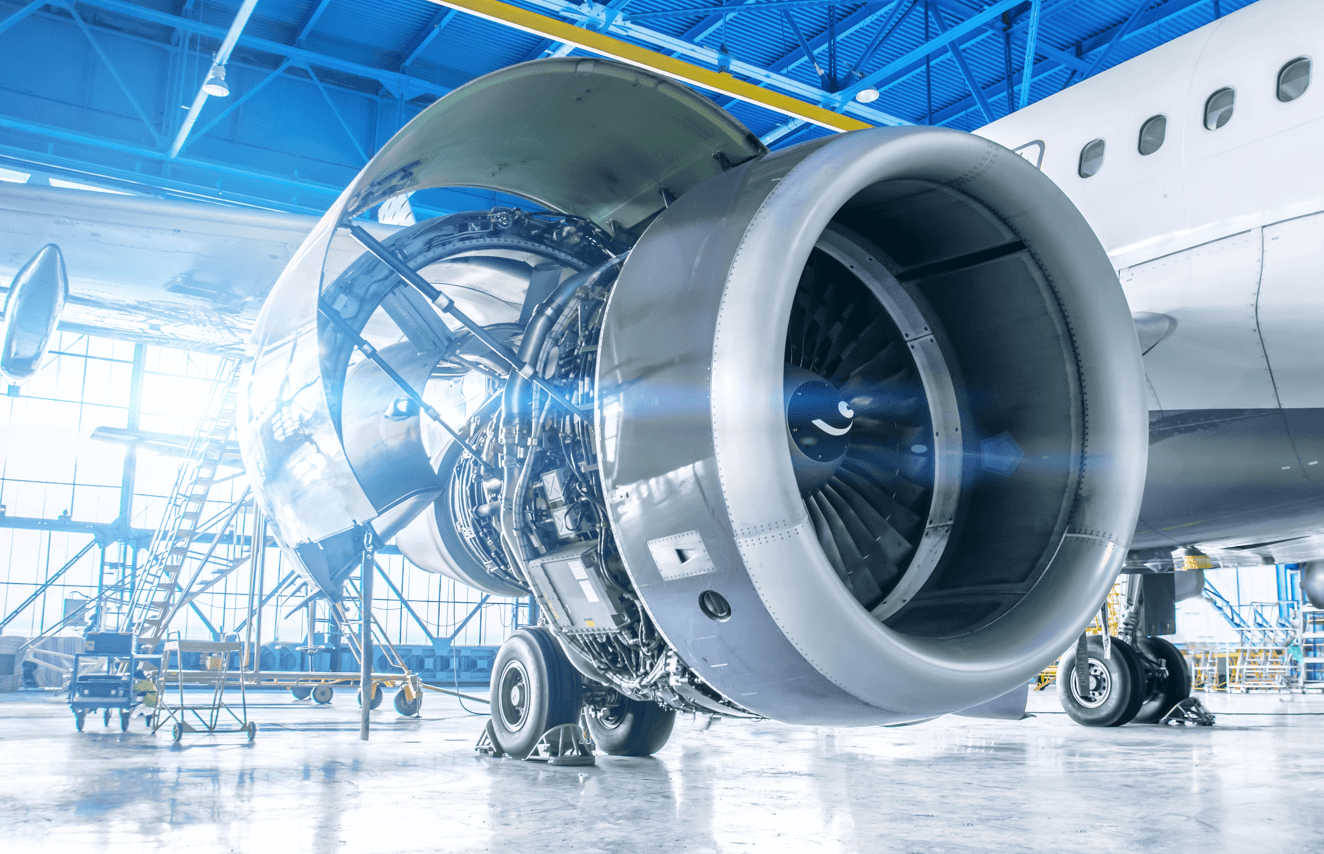

Alumina is one of the hardest technical materials available, ranking 9 on the Mohs scale. Unlike metals that weaken when exposed to heat, high-purity alumina retains its structure, even after extreme thermal cycles. Its abrasion resistance ensures long-lasting performance in components exposed to constant wear, including bearings, seals, and valves used in aerospace turbines and fuselage systems.

Exceptional Thermal Endurance

High-purity alumina withstands temperatures above 1600 °C in air and up to 2000 °C in vacuum environments. Its high thermal resistivity allows it to insulate or dissipate heat as needed. As the purity increases, so does thermal conductivity, making 4N and 5N grades ideal for parts like heat shields, exhaust nozzles, and thermal sensors. These grades resist thermal shock and protect mission-critical components from rapid expansion or failure.

Insulation You Can Count On

High dielectric strength and electrical insulation make high-purity alumina ideal for sensors, capacitors, and other electronic systems onboard aircraft. Its ability to prevent electrical breakdown ensures operational stability, especially under high voltages and extreme temperatures common in aerospace avionics.

Unmatched Chemical Stability

High-purity alumina resists corrosion from acids, alkalis, and environmental exposure. This inertness makes it the material of choice for outer space applications and aircraft systems exposed to saltwater or corrosive jet exhaust. Components retain mechanical and chemical integrity despite prolonged exposure to harsh operating conditions.

Real-World Aerospace Applications

From precision-engineered temperature and pressure sensors in combustion chambers to exhaust systems and bearing assemblies, high-purity alumina ceramics offer unmatched stability, thermal endurance, and mechanical strength. Their durability makes them ideal for both structural and high-performance electrical components.

Built for What Comes Next

As aerospace technologies demand more from their materials, Polar’s portfolio of advanced high-purity alumina grades is ready. Our TECHGuard™ products are engineered for critical applications, offering controlled surface area, high crystallinity, and exceptional purity. Whether in military defense, commercial aviation, or space systems, our materials help aerospace innovators stay ahead. Learn more about TECHGuard™ by contacting our team today.