The Polar Advantage

Spray-dried/Milled Powders

Polar’s patented process provides agglomerated powder through spray-drying or a de-agglomerated form through various milling process.

Customized Performance

Polar powder can be tailored to meet specific performance requirements for multiple applications. Particle size, surface area, and density can be tightly controlled to improve performance. Powder dopants and additives are available to meet special application performance criteria.

Consistent Purity and Particle Size

Polar provides 3N, 4N, and 5N powders with consistent purity and tight particle size distribution to improve product yields and repeatability

Alumina Powder Data Sheet

Request a Quote

3N (99.9%) Chemical Properties

| Elements | Concentration (ppmw) |

|---|---|

| Na | <300 |

| Mg | <50 |

| Si | <100 |

| Ca | <150 |

| Ti | <20 |

| Cu | <10 |

| Cr | <5 |

| Fe | <100 |

| K | <30 |

4N (99.99%) Chemical Properties

| Elements | Concentration (ppmw) |

|---|---|

| Na | <30 |

| Mg | <5 |

| Si | <10 |

| Ca | <10 |

| Ti | <5 |

| Cu | <5 |

| Cr | <5 |

| Fe | <20 |

| K | <10 |

5N (99.999%) Chemical Properties

| Elements | Concentration (ppmw) |

|---|---|

| Na | <4 |

| Mg | <1 |

| Si | <3 |

| Ca | <3 |

| Ti | <0.5 |

| Cu | <0.5 |

| Cr | <1 |

| Fe | <1 |

| K | <0.5 |

Physical Properties

| Property | Typical | Range |

|---|---|---|

| Specific surface Area BET, m2/g | 4-12 | 4-30 |

| D10 (Particle Size, um) | 0.1-0.2 | 0.1-5 |

| D50(Particle Size, um) | 0.4-0.8 | 0.1-40 |

| D90 (Particle Size, um) | 1.5-2 | 1.5-200 |

| Moisture, % | <0.15 | 0.1-0.2 |

Applications

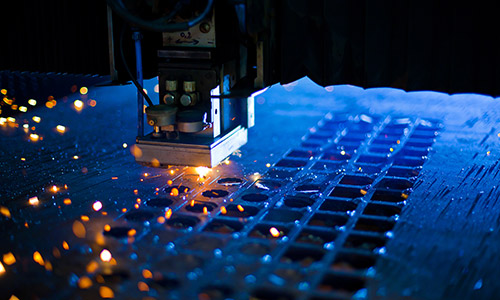

Cutting Tools

Apply to cutting tools for high performance and efficiency

Semiconductor Equipment Parts

High Purity Alumina for semiconductor device manufacturing

Ceramic Matrix Composites

For aerospace, medical and green energy industries

Other Powder Applications include: Fillers for Epoxy Molding Compounds, Battery Coatings, Medical and Dental Components, 3D Printed Ceramic Parts, Polishing Slurries and Pastes